We’ve all been there: a beautifully topped pizza, ready for the oven, is suddenly glued to the peel. It’s a frustrating moment that can quickly derail pizza night. The good news is that this is often an equipment problem, not a skill problem. The right tool makes all the difference, and the debate usually comes down to wood versus metal. A high-quality pizza peel metal is specifically designed to prevent sticking and ensure a smooth, effortless launch every single time. This guide will walk you through the features that make metal peels so effective and help you find the perfect one to eliminate sticky situations for good.

Key Takeaways

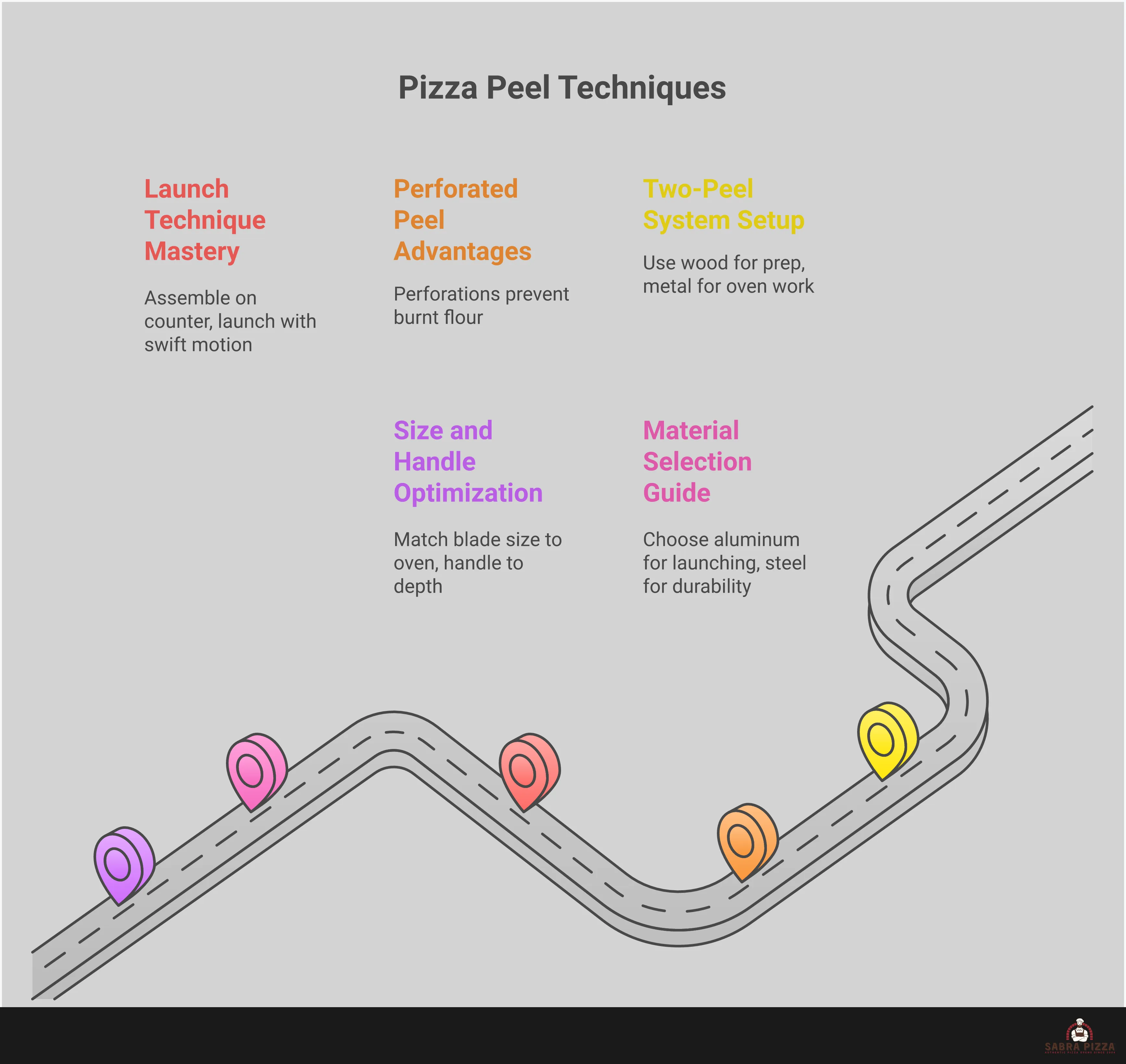

- Use wood for prep, metal for the oven: A wooden peel is perfect for assembling your pizza, as its surface helps prevent sticking. A thin metal peel offers the precision needed to launch, turn, and retrieve your pizza from the hot oven.

- Prioritize a lightweight, perforated design: When choosing a metal peel, look for lightweight aluminum for easier handling and a perforated blade. The perforations reduce friction and allow excess flour to fall away, preventing a burnt taste on your crust.

- Build on the counter, not the peel: To guarantee a smooth launch, always assemble your pizza on a well-floured surface and then slide the peel underneath. This simple step prevents moisture from making the dough stick to the metal.

Metal vs. Wood Pizza Peels: Which Is Better?

Choosing between a metal and a wood pizza peel is one of the first big decisions you'll make on your pizza-making journey. It’s a classic debate, and the truth is, there isn't one right answer for everyone. The best peel for you depends on your experience level, your oven, and your personal workflow. Think of it less as a competition and more about finding the right tool for the job.

Metal peels, typically made from aluminum or stainless steel, are prized for their thinness and durability. They slide under a cooked pizza with ease and can handle the intense heat of an oven without issue. Wood peels, on the other hand, have a classic, rustic appeal. Their porous surface is great for absorbing moisture and holding onto flour, which can help prevent a raw pizza from sticking as you build it. Many serious pizza makers actually use both—a wooden peel for preparation and a metal one for turning and retrieving. We’ll break down the key differences in performance, care, and ideal uses to help you decide which one (or both) belongs in your kitchen.

How They Perform Differently

The biggest difference you’ll feel between metal and wood is how they interact with the dough. Metal, especially aluminum, has a slick surface that minimizes friction. This makes launching your pizza into a hot oven a smooth, clean motion. Metal peels are also generally lighter and thinner, making them easier to maneuver for turning the pizza as it cooks and retrieving it when it’s done.

A wooden peel has a more porous texture. This can be an advantage when you’re first starting out, as a well-floured wooden surface can keep the dough from getting too sticky while you add your toppings. However, that same texture can make the final launch a bit tricky if you’re not quick enough or don’t use enough flour.

Durability and Material Care

When it comes to longevity, metal peels have a clear edge. Stainless steel and aluminum are tough materials that resist warping, cracking, and absorbing odors or stains from sauce and cheese. A quality metal peel is a long-term investment that can withstand accidental bumps and countless pizza nights. They are also incredibly easy to clean—just a quick wash with soap and water is all it takes.

Wooden peels require a bit more attention. They are prone to staining and can absorb strong smells from ingredients like garlic or onion. You should never soak a wooden peel or put it in the dishwasher, as it can warp or crack. While they are beautiful, they demand careful cleaning and proper storage to last. Though a good aluminum pizza peel might cost a little more upfront, its durability often makes it a more economical choice over time.

The Best Uses for Each Type

Many seasoned pizza chefs will tell you the secret isn’t choosing one over the other—it’s using each for what it does best. A wooden peel is fantastic for the preparation stage. You can build your pizza directly on its floured surface without the dough getting cold or sticky, which can sometimes happen on a metal peel.

However, when it’s time to launch, turn, and retrieve, metal peels are often preferred by pros. Their thin blades slip easily under the pizza, whether it’s raw or fully cooked. Perforated metal peels take this a step further by allowing excess flour to fall away before the pizza hits the oven. This simple feature helps prevent the flour from burning on your pizza stone, which avoids a bitter taste and reduces smoke.

What to Look for in a Metal Pizza Peel

Once you’ve decided a metal peel is right for you, the next step is picking the perfect one. Not all metal peels are created equal, and the right choice depends on your oven, your pizza-making style, and your personal preferences. A great metal peel feels like an extension of your arm, giving you the confidence to launch and retrieve pizzas with ease. To find that perfect match, let's look at the key features that separate a good peel from a great one. From the material it’s made of to the design of its handle, every detail matters.

Quality of Materials and Build

The first thing to consider is what the peel is made of. Most metal peels are either aluminum or stainless steel. Aluminum pizza peels are popular because they are lightweight and easy to handle, making them a fantastic choice for home chefs. They won’t rust, and their lighter weight reduces arm fatigue when you’re making multiple pizzas. Stainless steel, on the other hand, is heavier but incredibly durable. It’s a workhorse material that can stand up to frequent use and the occasional bump against the oven wall without denting or warping.

Blade Design and Thickness

The business end of the peel—the blade—is where the magic happens. You want a blade that’s thin, especially at the leading edge. A thin, beveled edge makes it much easier to slide the peel cleanly under a raw pizza without messing up your toppings. The blade should also be smooth and strong enough to hold the weight of a fully loaded pizza without flexing. While wood peels can be thick, a well-designed metal peel offers the strength you need in a much thinner profile, giving you more precision and control.

Handle Length and Grip

Don’t overlook the handle—it’s your connection to the peel and crucial for both safety and control. The right handle length depends entirely on the depth of your pizza oven. For deep, wood-fired ovens, you’ll need a long handle to keep your hands safely away from the intense heat. For smaller countertop or backyard ovens, a shorter handle offers better maneuverability in tight spaces. Look for a handle with a comfortable, secure grip that feels balanced in your hand. This will make it easier to perform the quick, decisive movements needed to launch your pizza perfectly.

Balance and Weight

Imagine holding a heavy, unbalanced peel with a fully-loaded pizza perched on top. It’s a recipe for disaster. The overall weight and balance of the peel are critical for easy use. A lighter peel is generally easier to manage, especially for beginners. This is one reason why many chefs prefer perforated peels, as the holes remove metal, making the peel lighter without sacrificing strength. A well-balanced peel, where the weight is distributed evenly between the blade and the handle, will feel more stable and give you greater confidence as you move your pizza.

Special Surface Treatments

Some of the best metal peels come with special features designed to make your life easier. The most common is perforation. Perforated pizza peels have holes across the blade surface that serve two key purposes. First, they allow excess flour to fall away from the bottom of the dough before it goes into the oven. This prevents the flour from burning, which can create smoke and a bitter taste. Second, the perforations reduce friction, helping the pizza slide off the peel and onto the hot stone with almost no effort. It’s a simple feature that makes a huge difference.

Exploring the Types of Metal Peels

Once you’ve decided on a metal peel, you’ll find they come in a few different styles. The material, blade design, and size all play a role in how the peel performs. Understanding these differences will help you find the perfect tool for sliding your pizzas into the oven with confidence and ease. Let’s break down the most common types of metal peels so you can choose the right one for your setup.

Aluminum vs. Stainless Steel

The two most common materials for metal pizza peels are aluminum and stainless steel, and each has its own distinct advantages. Aluminum peels are prized for being lightweight and easy to handle. Their naturally slick surface helps raw pizza dough slide off smoothly, which is why many pizza makers prefer them as their primary launching peel. An aluminum peel makes the transfer from your prep counter to the hot pizza stone feel effortless.

On the other hand, stainless steel peels are the heavy-duty workhorses of the pizza world. They are incredibly strong, durable, and resistant to dings or bending. While a bit heavier than aluminum, their rigidity makes them excellent for turning pizzas inside the oven and retrieving them once they’re perfectly cooked. Stainless steel is also very easy to clean and maintain, ensuring it will last for years.

Perforated vs. Solid Blades

You’ll also notice that metal peels come with either a solid or a perforated blade. Perforated peels have holes across the surface, and they serve a brilliant purpose. As you scoop up your prepared pizza, these perforations allow excess flour or cornmeal to fall away. This is a huge plus because less flour on the peel means less flour burning on your oven floor, which can create smoke and a bitter taste. The perforations also reduce friction, helping the pizza glide off the peel even more easily.

Solid blade peels are the classic choice and are still incredibly effective. They offer a sturdy, continuous surface that can feel more forgiving, especially when you’re first learning. There’s no risk of dough sagging through any holes. They are also generally a bit easier to clean since you don’t have to worry about bits of cheese or dough getting stuck in the perforations.

Finding the Right Size and Shape

Choosing the right size and shape for your peel is crucial for a stress-free pizza night. First, consider the size of your oven opening and the size of the pizzas you plan to make. Your launching peel needs to be wide enough to fully support your uncooked pizza base—you don’t want any part of it drooping over the sides. A good rule of thumb is to choose a peel that is slightly smaller than your pizza stone but large enough for your pizza.

Peels also come in two primary shapes: rectangular and round. Rectangular peels provide a large, stable surface area, making them ideal for building your pizza on and launching it into the oven. Round peels, often called turning peels, are smaller and designed for rotating the pizza while it’s cooking to ensure an even bake.

Peels for Home Cooks vs. Pros

While you don’t need to be a professional pizzaiolo to use pro-grade tools, it’s helpful to know what sets them apart. For most home cooks, a single, high-quality aluminum peel is a fantastic starting point. Its lightweight feel and slick surface make launching pizzas much less intimidating. Many home pizza makers find a 12- or 14-inch rectangular peel is versatile enough for all their needs.

Professionals—and serious home enthusiasts—often use a two-peel system. They’ll use a larger aluminum peel (often perforated) exclusively for launching raw pizzas and a smaller, round stainless steel turning peel for managing the pizza inside the hot oven. This specialized approach gives them maximum control at every stage of the cooking process. Ultimately, the best peel is the one that makes you feel comfortable and confident in your kitchen.

How to Choose the Perfect Metal Peel

Finding the right metal peel feels a lot like finding the perfect kitchen knife—it should feel like an extension of your hand. The ideal peel for you will depend on your oven, the size of pizzas you love to make, and your personal style in the kitchen. Are you a weekend warrior firing up a few pies for the family, or are you aiming for pizzeria-level perfection with every launch? Answering that question is the first step.

As you start looking, you’ll see a wide range of options, from simple, functional aluminum peels to high-tech, perforated stainless steel models. It’s easy to get overwhelmed, but don’t worry. We’re going to break down the key factors to consider, from the practicalities of size and weight to the finer details of blade design. We’ll help you figure out which features are must-haves and which are just nice extras, so you can find a fantastic tool whether you’re on a budget or ready to invest in a top-of-the-line peel. Think of this as your personal guide to choosing a partner for your pizza-making adventures.

Consider Size and Weight

The first thing to think about is how the peel will physically work with you and your oven. The head of the peel should be slightly smaller than your oven opening and large enough to comfortably hold your pizzas. A peel that’s too big will be clumsy to use, while one that’s too small can make launching a perfectly round pizza a real challenge. Weight is just as important. Aluminum pizza peels are significantly lighter than their stainless steel counterparts, which makes a huge difference when you’re making multiple pizzas. A lighter peel is easier to maneuver, giving you more control and reducing arm fatigue.

Match the Peel to Your Needs

Your cooking habits should guide your choice. Are you meticulous about using just the right amount of flour, or do you tend to be a bit more generous to prevent sticking? If you find yourself using a lot of flour, a perforated peel is a fantastic option. The small holes allow excess flour to fall away before the pizza hits the hot stone, which means less smoke and no bitter, burnt-flour taste on your crust. Solid-blade peels are also great and can feel a bit more stable for beginners. There’s no wrong answer—it’s all about choosing the tool that best aligns with your technique and helps you make your best pizza.

Find a Great Peel on a Budget

You don’t need to spend a fortune to get a high-quality, reliable metal peel. Many excellent, budget-friendly options will serve you well for years. Look for peels made from a solid piece of anodized aluminum with a securely attached handle. While they might not have advanced features like perforations or a beveled edge, a well-made basic peel is a workhorse in the kitchen. You can find a great selection of pizza peels at restaurant supply stores that offer professional-grade durability without the premium price tag. Focus on sturdy construction and a comfortable feel, and you’ll have a tool that gets the job done beautifully.

What You Get with Premium Peels

If you’re ready to invest in a tool that offers superior performance and longevity, a premium peel is worth considering. These are often made from high-grade stainless steel or specially treated aluminum. Stainless steel pizza peels are incredibly durable, resistant to dings and scratches, and often feature a smoother surface for an effortless launch. Premium models may also have thoughtful design elements like beveled edges that make it easier to slide under dough, heat-resistant handles for added safety, and a perfectly balanced feel. These peels are built for enthusiasts who appreciate fine craftsmanship and want the absolute best tool for their passion.

Our Favorite Brands and Models

When it comes to trusted brands, we often recommend Alfa Forni and Gi.Metal to our customers. Alfa Forni offers a range of peels that are perfectly matched to their ovens, ensuring a seamless experience. Gi.Metal is another industry leader, renowned for its innovative designs, especially its perforated peels. Many serious home cooks find that a perforated turning peel is a game-changer, allowing for quick, precise movements inside the oven. Ultimately, the best model is one that feels right in your hands and complements your oven and cooking style, so use these recommendations as a starting point for finding your perfect match.

How to Use and Care for Your Metal Peel

Your metal pizza peel is the key to moving your creation from the counter to the hot oven stone. Getting the hang of it can feel a little tricky at first, but with a few simple techniques, you'll be launching pizzas like a seasoned pro. The goal is a swift, confident motion that lets the pizza slide gracefully into the oven without losing its shape or toppings. It’s all about preparation and practice. Once you master the launch, you’ve conquered one of the biggest hurdles in home pizza making. Proper care is just as important—a well-maintained peel will last for years and perform reliably every time you fire up the oven. Let's walk through the essential steps for using and caring for your metal peel, from preventing sticky situations to simple cleanup.

Tips for a Perfect Launch

The "launch" is that moment of truth when your pizza slides from the peel into the hot oven. The secret is a quick, decisive movement. After you slide the peel under your prepared pizza, give it a little shake to make sure it’s not sticking. When you get to the oven, position the tip of the peel where you want the back of the pizza to land. Then, in one smooth motion, pull the peel back toward you, letting the pizza slide off onto the stone. Think of it like pulling a tablecloth out from under a set of dishes. Hesitation is your enemy here, as it gives the dough time to stick. Don't worry if your first few attempts aren't perfect—it's a skill that gets easier with every pizza you make.

How to Keep Dough from Sticking

A sticky pizza is the fastest way to ruin pizza night. The best way to prevent the dough from sticking is to create a barrier between it and the peel. Before sliding the peel under your pizza, give it a light dusting of semolina or bread flour. These coarser flours act like tiny ball bearings, helping the pizza glide right off. If you have a perforated peel, even better—the holes allow excess flour to fall away, so you don't get a burnt flour taste on your crust. The most important rule? Assemble your pizza on a floured countertop, not on the peel itself. The longer the wet dough sits on the metal, the more likely it is to stick.

Managing Peel Temperature

Metal peels, especially aluminum ones, are great conductors of heat. While this is useful in the oven, you want to keep your peel at room temperature before a launch. If the peel gets warm, it can make the dough soft and sticky, increasing the chances of a failed launch. Store your peel away from the hot oven or any other heat source while you're prepping. The natural slipperiness of a cool aluminum surface is one of its biggest advantages, as it helps the pizza slide off with minimal effort. Just remember: a cool peel is your best friend for a clean, easy transfer from counter to stone.

Simple Cleaning and Storage

Cleaning your metal peel is straightforward. After it has cooled down completely, wash it by hand with warm, soapy water and a non-abrasive sponge. Avoid harsh scouring pads that could scratch the surface. The most critical step is to dry it thoroughly right away to prevent any water spots or potential corrosion, especially with certain types of metal. If you have a perforated peel, you might need a brush to gently clear any baked-on cheese or flour from the holes. Once it's clean and dry, store it by hanging it up or placing it somewhere flat where it won't get bent or damaged.

Common Mistakes to Avoid

Two common mistakes can lead to a pizza disaster. First, never build your pizza directly on the metal peel. When you add sauce and wet toppings, the moisture will seep through the flour and cause the dough to glue itself to the surface. Always prep on your counter and slide the peel underneath right before launching. Second, make sure your peel is the right size for your pizza. If the dough hangs over the edges, it’s nearly impossible to get a clean launch. Mastering these basic pizza peel techniques will save you a lot of frustration and ensure your beautiful pizza makes it into the oven in one piece.

Where to Buy Your Metal Pizza Peel

Now that you know what to look for, let's talk about where to find the perfect metal peel for your setup. You have plenty of great options, from specialty stores to large online retailers. The right place for you will depend on whether you prioritize selection, price, or convenience. Here are a few of our go-to spots and what to keep in mind as you shop.

Our Recommended Retailers

Finding a quality metal peel is easy when you know where to look. For a massive selection that serves both home cooks and restaurant professionals, WebstaurantStore is a fantastic resource. They offer wholesale pricing and fast shipping, which is a huge plus if you're outfitting a serious outdoor kitchen. If you prefer a more curated experience, The Pizza Oven Store USA specializes in pizza-making gear and carries some excellent perforated stainless steel peels. And of course, there’s Amazon. Its vast marketplace and customer reviews make it a convenient place to compare different brands and models all at once.

What to Expect to Pay

The price of a metal pizza peel can vary quite a bit, typically ranging from around $35 to well over $50. For example, you might find a basic Winco aluminum peel for under $40, while more specialized or premium models can climb higher. The cost usually reflects the quality of the materials, the brand's reputation, and any special features like a perforated blade or a heat-resistant handle. When you’ve invested in a premium pizza oven, it makes sense to pair it with a high-quality peel that will perform well and last for years. Think of it as a key part of your pizza-making toolkit.

Why Warranties Matter

While a pizza peel is a relatively simple tool, a good warranty is always a sign of a manufacturer's confidence in their product. When you're choosing a peel, especially a more expensive one, check to see if it comes with any kind of warranty. This protects you from any defects in materials or craftsmanship. A company that stands behind its product with a solid warranty is usually a safe bet. It gives you peace of mind knowing that your investment is protected and that you've chosen a tool built to last through countless pizza nights.

Tips for Finding the Best Deal

Getting a great price on a quality peel feels almost as good as pulling a perfect pizza from the oven. One of the best ways to save is by keeping an eye out for limited-time deals on Amazon, where you can often find top-rated peels at a nice discount. It’s worth checking periodically, especially around major holidays. Additionally, retailers like WebstaurantStore are known for their competitive pricing year-round. Because they cater to the restaurant industry, their prices are often lower than standard retail, making them a reliable source for finding a great deal without sacrificing quality.

Ready to Upgrade? Advanced Peel Features

Once you’ve mastered the basics of launching and turning pizzas, you might notice the small ways your equipment helps or hinders your process. If you’re ready to move beyond a starter peel, you’ll find a world of advanced features designed to make your pizza-making more precise, consistent, and enjoyable. These aren’t just bells and whistles; they are thoughtful innovations that address the common challenges every pizza maker faces, from a sticky launch to managing a ripping hot oven.

Upgrading your peel is about gaining more control and confidence. Advanced peels often feature specialized materials, ergonomic designs, and surface treatments that work together to create a seamless workflow. Think lighter-weight metals that reduce fatigue, handles that stay cool to the touch, and blades engineered for the perfect slide. Investing in a high-quality tool means you can focus less on wrestling with your dough and more on the art of the bake. These premium features are what separate a good pizza night from a truly great one, giving you the performance you need to create pizzeria-quality results right in your own backyard.

The Benefit of Non-Stick Coatings

There’s nothing more frustrating than a perfectly topped pizza sticking to the peel at the last second. This is where advanced surface treatments come in. Many high-end aluminum peels have a non-stick or hard-anodized coating that creates an incredibly smooth surface. This finish is designed to minimize friction between the dough and the peel, allowing your pizza to glide off effortlessly into the oven. It’s a simple feature that makes a huge difference, especially when you’re working with high-hydration doughs that are prone to sticking. This smooth release helps maintain the pizza’s shape and ensures your toppings stay exactly where you placed them.

Heat-Resistant Handles and Tech

When you’re working with an oven that’s pushing 900°F, the last thing you want to worry about is a hot handle. Advanced peels often feature handles made from heat-resistant polymers or composites that stay cool and comfortable to hold, even when the blade is hot. Beyond the material, the design is key. Many premium peels are engineered to be lighter and easier to maneuver, which gives you better control as you place and turn your pizza. This combination of smart materials and ergonomic design provides both safety and precision, allowing you to work confidently around the intense heat of your oven.

Sleek, Modern Designs

Modern pizza peels aren’t just functional; they’re also designed with performance in mind. One of the most popular innovations is the perforated peel. These peels feature a pattern of holes across the blade surface. This design has two major benefits: first, it significantly reduces the weight of the peel, making it less tiring to use. Second, the perforations allow excess flour to fall away from the bottom of the dough as you prep your pizza. This means less burnt flour on the oven floor and a cleaner, better-tasting crust. The sleek look is just a bonus to the smarter functionality.

What Makes a Peel "Professional-Grade"?

So, what exactly elevates a peel to "professional-grade" status? It comes down to durability and construction. Professional peels are built to withstand the demands of constant use in a commercial kitchen or a serious home setup. They are often made from high-gauge stainless steel or hard-anodized aluminum, materials chosen for their strength and longevity. A professional-grade peel is resistant to bending, warping, and the impacts that can happen during a busy cooking session. This robust build ensures reliable performance every time you fire up the oven, making it a worthwhile investment for any dedicated pizza enthusiast.

Related Articles

- Pizza Peel Sets for Sale: Metal & Wooden Pizza Peel Sets

- WPPO™ Traditional Aluminum Pizza Peel w/ Wood Handle

Frequently Asked Questions

Do I really need both a wood and a metal pizza peel? You definitely don't need both, but many pizza makers find that using one of each makes the process much smoother. A wooden peel is fantastic for building your pizza because its porous surface absorbs a bit of moisture and holds flour well, which helps prevent the dough from sticking during prep. A thin metal peel, however, is superior for launching the pizza into the oven and for turning it during the bake. If you're only going to buy one, a quality metal peel is the more versatile choice.

What's the biggest advantage of a perforated metal peel? The holes in a perforated peel serve two brilliant purposes. First, they allow excess flour from the bottom of your pizza to fall away before it enters the oven. This prevents that flour from burning on your hot pizza stone, which can create a bitter taste and a lot of smoke. Second, the perforations reduce friction and surface area, helping the raw pizza slide off the peel more easily for a perfect, stress-free launch.

My pizza always sticks to my metal peel. What am I doing wrong? This is the most common frustration, and it usually comes down to one of two things. First, never build your pizza directly on the metal peel. The longer the wet dough sits on the metal, the more likely it is to stick. Always assemble your pizza on a well-floured countertop. Second, right before you slide the peel under the pizza, give the peel a light dusting of semolina or flour. This creates a layer of tiny "ball bearings" that helps the pizza glide right off.

What's the most important feature for a beginner to look for in a metal peel? If you're just starting out, focus on finding a peel that is lightweight and well-balanced. A heavy or clumsy peel can feel intimidating and make the launching motion much more difficult. A lightweight aluminum peel is often the best choice for beginners because it's easy to handle and maneuver. This will help you build the confidence you need to perform that quick, decisive movement required for a perfect launch.

How do I choose the right size peel for my oven? The head of your peel should be large enough to fully support the pizzas you plan to make, but it must be slightly smaller than your oven's opening and your pizza stone. You need a little wiggle room on each side to move it around. The handle length is just as important and depends on the depth of your oven. For deeper ovens, you'll need a longer handle to keep your hands safely away from the heat, while a shorter handle offers more control for smaller, countertop ovens.